Noise attenuation improves the resolution of seismic images, but the denoising processes can be an expensive and time-consuming procedure. This approach improves the reliability of automated quality control (QC) of the seismic data denoise process and was tested on a full production scale. It requires very limited human interaction and can be used to automate and assist the human quality controller.

Denoising is typically applied by optimizing key parameters of a sub-set of the survey data (known as test lines) to ensure noise has been sufficiently attenuated without signal distortion. The success of the denoise process is visually assessed before the optimized parameters are applied to the entire survey. As the volume of a test line is small, visual assessment at this stage generally finds no issues. Using these fixed parameters for the remaining large dataset can, therefore, be sub-optimal in other areas where there are different noise characteristics, or during time intervals when the signal can change dramatically due to weather fluctuations, so QC is crucial.

As the volume of data in a typical survey has increased over time, coincidentally so has the amount of time and resources required for reliable QC of denoise processing. To minimize QC user interaction, a supervised learning approach is suggested in the First Break article. It proposes a machine learning solution that can be used to classify filtering results.

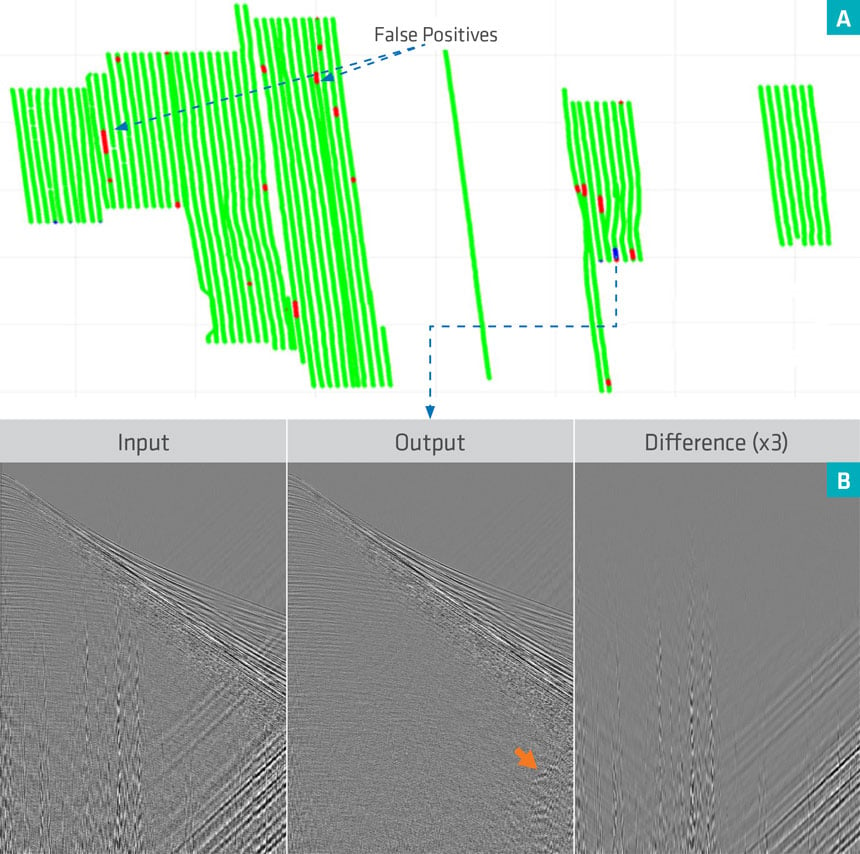

The main idea of the proposed QC system is to formulate an automatic QC as a supervised classifier. Attributes are computed from training seismic data lines which are then used to train a support vector machine, thereby providing a means to significantly faster QC reporting as user interaction is restricted solely to the training phase. Ultimately, an attribute-based QC could naturally evolve as an intelligent and automated system.

The full production test of the proposed system picked out areas in the data with clear residual noise. Reducing the rate of false positives is a challenge which can be overcome by using informative attributes that can give a better sampling of the filtering performance.

The supervised learning approach described in the article can significantly improve project turnaround and can be potentially applied to QC processes beyond noise attenuation, such as multiple attenuation.

Contact a PGS expert

If you have questions related to our business please send us an email.